- ZHUHAI JIALI HARDWARE CO.,LTD.

- +86-756-8586520

Grade 8 hot-dip galvanized elastic gasket GB93 anti-loosening gasket open gasket M16-M30

- Product description:In the industrial fastening system, the selection of spring washers must balance "long-term reliability" with "cost controllability" — Grade 8 hot-dip galvanized spring washers GB93 have become a high

Centered on Grade 8 high-strength material (with tensile strength ≥ 800MPa and yield strength ≥ 640MPa), it is combined with hot-dip galvanizing surface treatment (zinc coating thickness ≥ 85μm) and strictly complies with the structural design of China's national standard GB93 (open-type elastic structure). It not only solves the pain points of ordinary spring washers, such as easy rusting and failure, but also reduces the comprehensive use cost through the advantages of large-scale production and adaptability, achieving a dual breakthrough in "durability" and "economy".

I. Material and Process: Laying a Solid Foundation for "Durability"

The durability of Grade 8 hot-dip galvanized spring washers GB93 first comes from the coordinated optimization of material and surface treatment. In terms of material, Grade 8 strength corresponds to high-quality alloy structural steels (such as 65Mn and 50CrV4). After quenching and tempering, these steels have excellent elastic limit and fatigue resistance. In high-frequency vibration scenarios (e.g., motor base connections), the spring washers can continuously provide anti-loosening preload through repeated elastic deformation. Even when bearing dynamic loads of 500-800N for a long time, they are not prone to permanent deformation or fracture, and their fatigue life is 3-5 times that of ordinary Grade 4.8 spring washers.

The hot-dip galvanizing process provides the spring washers with a "corrosion-resistant armor". Compared with electro-galvanizing (with a zinc coating thickness of only 10-20μm), hot-dip galvanizing involves immersing the spring washers in molten zinc liquid (at approximately 450℃), forming a dense zinc-iron alloy layer and pure zinc layer on the surface. The zinc coating thickness generally reaches 85-120μm, and its bonding force with the substrate is extremely strong. This coating can effectively isolate air, moisture, and corrosive media (such as rainwater, industrial dust, and mild acids and alkalis). Even in outdoor humid environments or corrosive atmospheres in industrial workshops, it can ensure that the spring washers do not show obvious rust within 3-5 years; even if the local zinc coating is damaged, the surrounding zinc coating can protect the substrate through the "sacrificial anode" effect, further extending the service life. For example, in the bolt connection of outdoor distribution boxes, Grade 8 hot-dip galvanized spring washers GB93 can resist rain erosion and salt in the air, preventing bolts from loosening due to the loss of elasticity of rusted spring washers and ensuring the long-term safe operation of distribution boxes.

II. Standard and Adaptability: Amplifying the Advantages of "Economy"

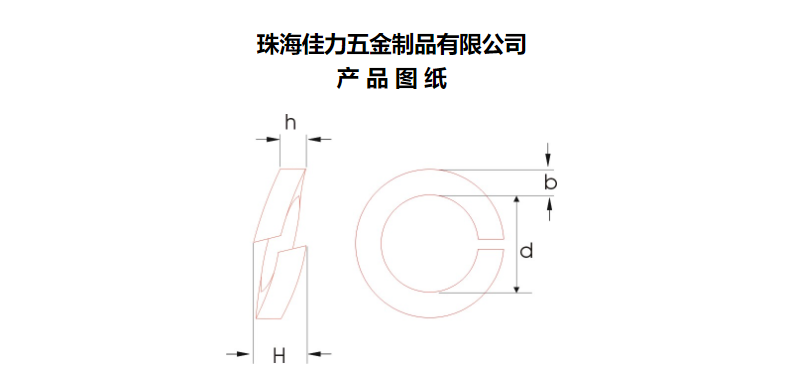

The economy of Grade 8 hot-dip galvanized spring washers GB93 does not simply refer to low unit price, but is reflected in the comprehensive cost advantages of "wide adaptability, easy procurement, and low maintenance". Firstly, China's national standard GB93 defines unified dimensional specifications for them — ranging from small sizes matching M3 bolts (inner diameter 3.2mm, outer diameter 6mm, thickness 1mm) to large sizes matching M30 bolts (inner diameter 31mm, outer diameter 50mm, thickness 6mm), all with clear parameter specifications. This means they can be used with most Grade 8.8 and above high-strength bolts on the market, without the need for custom-made special specifications, significantly reducing procurement and inventory costs. In the automobile parts production line, a set of Grade 8 hot-dip galvanized spring washers GB93 can be adapted to multiple bolt models, avoiding low assembly efficiency caused by inconsistent washer specifications and indirectly reducing labor costs.

Secondly, the "maintenance-free" characteristic of the hot-dip galvanizing process further reduces the use cost. Ordinary non-galvanized spring washers need regular rust-proof oil coating or replacement in humid environments, while Grade 8 hot-dip galvanized spring washers GB93 require almost no additional maintenance during their service life. Taking the connection of construction scaffolding as an example, traditional black-finish spring washers need to be inspected for rust and replaced every six months, while Grade 8 hot-dip galvanized spring washers GB93 can be used with scaffolding for 2-3 project cycles (about 1-2 years) without maintenance. This not only reduces the replacement frequency but also lowers the safety risks and labor costs of high-altitude operations.

In addition, large-scale production makes the unit price of Grade 8 hot-dip galvanized spring washers GB93 more competitive. Since they comply with national standards and have a wide range of application scenarios, most domestic fastener manufacturers produce them in large quantities, ensuring sufficient market supply. The unit price for bulk procurement can be as low as 0.1-0.5 yuan per piece (depending on specifications), which is only 10%-20% higher than that of ordinary electro-galvanized spring washers, but their service life is 2-3 times that of the latter. From the perspective of "life-cycle cost", the cost-performance advantage is significant.

III. Application Scenarios: Practical Verification of Durability and Economy

1. Construction and Municipal Engineering: A Cost-Effective Choice for Outdoor Scenarios

In the installation of municipal street lamp poles and traffic signal brackets, Grade 8 hot-dip galvanized spring washers GB93 must withstand outdoor exposure to wind, sun, and rain erosion. Their hot-dip galvanized coating can effectively resist atmospheric corrosion, preventing bracket loosening caused by rusted spring washers; Grade 8 strength can bear the self-weight of street lamp poles and strong wind loads, ensuring structural stability. Compared with stainless steel spring washers, the unit price of Grade 8 hot-dip galvanized spring washers GB93 is only 1/3-1/2 of the former, and they have stronger adaptability, which can save hundreds of thousands of yuan in fastener costs in large-scale municipal engineering projects.

2. Agricultural Machinery and Heavy Equipment: A Low-Maintenance Choice Under High Loads

When agricultural machinery (such as tractors and harvesters) operates in the field, it often comes into contact with soil, pesticides, and irrigation water, which places high requirements on the corrosion resistance and strength of spring washers. The hot-dip galvanized coating of Grade 8 hot-dip galvanized spring washers GB93 can resist corrosion from moisture in the soil and pesticide residues, and Grade 8 strength can bear the vibration and impact loads generated during mechanical operation, preventing component loosening caused by spring washer failure. Compared with ordinary spring washers, they do not require frequent disassembly and maintenance, reducing the downtime of agricultural machinery and indirectly improving agricultural production efficiency, which meets the "economical and practical" needs of agricultural equipment.

3. Household Appliances and Industrial Equipment: An Adaptable Tool for Mass Production Scenarios

In the assembly of household appliances such as washing machines and air conditioner outdoor units, Grade 8 hot-dip galvanized spring washers GB93 can be adapted to the bolt connections of components such as motors and casings. Their standard dimensions in line with GB93 ensure precise matching with household appliance bolts, facilitating automated assembly line operations; the hot-dip galvanized coating can resist moisture in the use environment of household appliances (such as water vapor inside washing machines), preventing the impact of spring washer rust on the service life of household appliances. Due to low bulk procurement costs and wide adaptability, they have become an important choice for household appliance manufacturers to control production costs, and their durability also reduces the replacement rate of fasteners in household appliance after-sales maintenance.

From outdoor engineering to industrial production, Grade 8 hot-dip galvanized spring washers GB93 have always taken "durability as the foundation and economy as the wing". Through the coordination of material, process, and standard, they not only meet the requirements for fastening reliability in various scenarios but also help users control comprehensive costs, becoming a model of balancing "cost-performance" and "practicality" in the industrial field.