- ZHUHAI JIALI HARDWARE CO.,LTD.

- +86-756-8586520

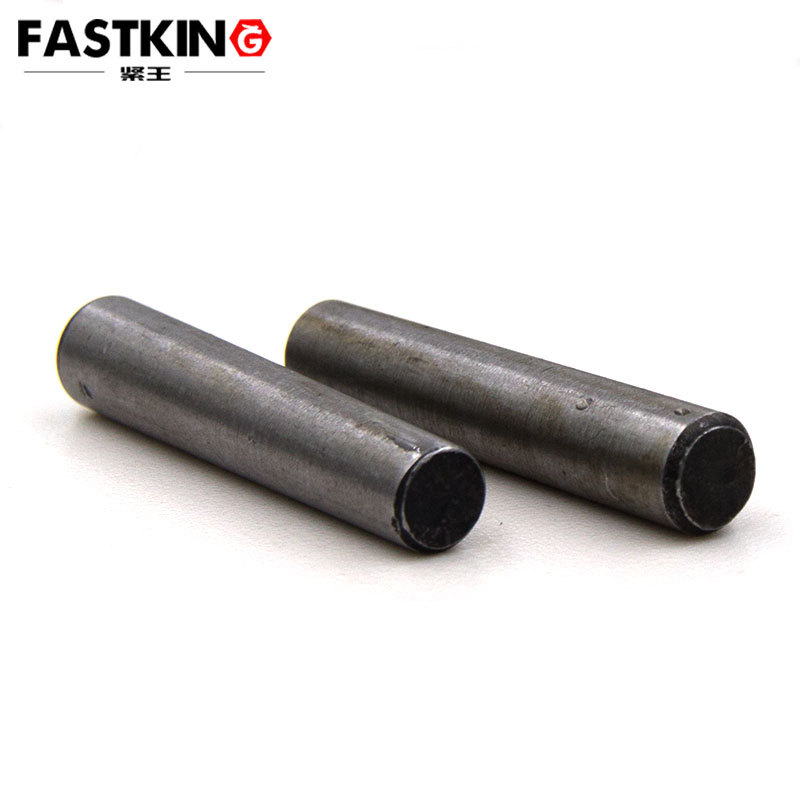

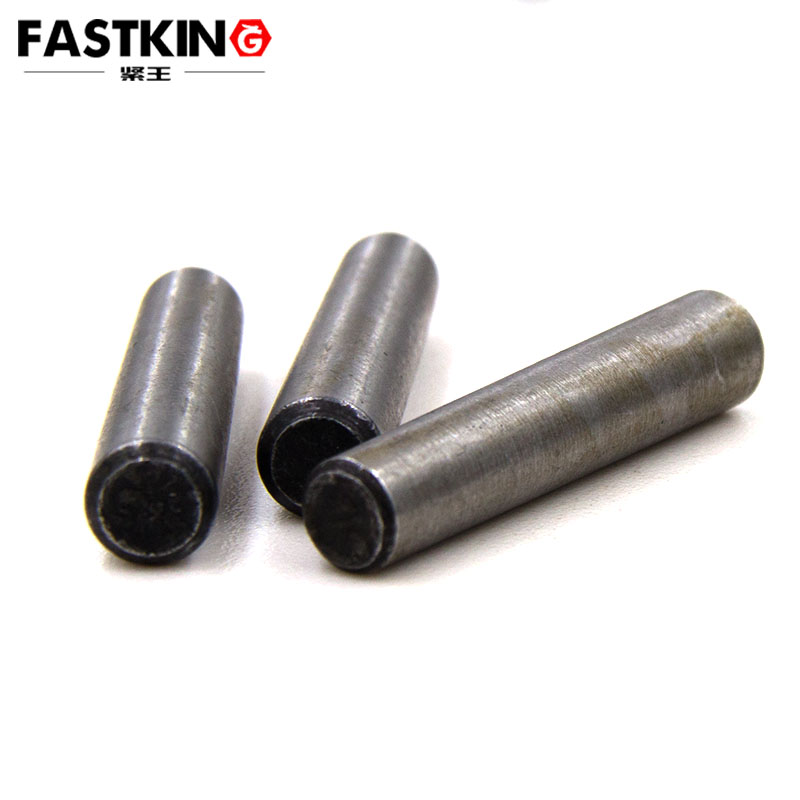

40Cr alloy steel tapered pins are flat at both ends of the flat black GB117

- Product description:In precision fastening scenarios such as mechanical manufacturing and equipment assembly, taper pins act as key components for positioning and connection, and their performance directly impacts the st

I. Core Advantages: Dual Guarantee of Material and Craftsmanship

40Cr alloy steel, as the base material of this taper pin, serves as the core support for its performance. With a moderate carbon content, 40Cr alloy steel, after adding chromium, not only significantly improves the material's hardenability (reaching a hardness of HRC28-32 after heat treatment) but also possesses excellent strength, toughness, and wear resistance. It can withstand large impact loads and shear forces, preventing deformation or fracture during long-term use. Compared with ordinary carbon steel taper pins, 40Cr taper pins have a 3-5 times longer service life under high-strength working conditions, making them particularly suitable for components with strict fastening strength requirements, such as machine tool spindles and automobile gearboxes.

The "flat ends with black oxide finish" treatment adds key protective and practical properties to the taper pin. Through chemical conversion, black oxide treatment forms a black oxide film (mainly composed of triiron tetroxide) with a thickness of approximately 1-3μm on the pin surface. This film adheres tightly to the metal surface, effectively isolating air, moisture, and corrosive media, and improving the pin's rust resistance to more than twice that of ordinary untreated parts. Even in humid environments or those with slight oil contamination, it can maintain stable performance for a long time. Meanwhile, the uniformly matte black surface after black oxide treatment not only avoids the interference of metal reflection on the operating field of vision but also reduces sliding friction between the pin and connected components, enhancing positioning accuracy during assembly.

II. Standard Specifications: Consistency and Reliability Brought by GB117

As a fastener conforming to the national standard GB117, the 40Cr alloy steel taper pin with flat ends and black oxide finish has strict requirements for dimensional accuracy, appearance quality, etc., ensuring the product's universality and interchangeability. According to GB117, the taper of this type of taper pin is uniformly 1:50. This taper design allows the pin to automatically center through axial force during assembly, fit tightly to the inner wall of the tapered hole, form a reliable interference fit, and effectively prevent loosening. In addition, the standard clearly defines indicators such as the pin's diameter tolerance (e.g., d6 grade accuracy), parallelism of the flat ends (error not exceeding 0.02mm/m), and adhesion of the black oxide film (no peeling in cross-cut tests), avoiding assembly difficulties or positioning failures caused by dimensional deviations of non-standard parts.

For enterprises, selecting taper pins that comply with GB117 can significantly reduce supply chain management costs. Whether purchasing from different suppliers or replacing parts during equipment maintenance, standardized dimensions and performance parameters ensure seamless adaptation of parts without additional processing or adjustment, improving production and maintenance efficiency. For example, in the connection of roller shafts in textile machinery, using taper pins meeting GB117 can increase the assembly qualification rate from 85% (for non-standard parts) to over 99%, reducing rework losses caused by mismatched parts.

III. Application Scenarios: Wide Adaptation from Industrial Equipment to Precision Instruments

The performance advantages of the 40Cr alloy steel taper pin with flat ends and black oxide finish (GB117) enable its in-depth application in multiple fields. In the mechanical manufacturing field, it is often used for positioning and connecting machine tool worktables and guide rails. Relying on the high strength of 40Cr material and the centering effect of the 1:50 taper, it ensures that the coaxiality error of the worktable during high-speed movement does not exceed 0.01mm, guaranteeing processing accuracy. In the automotive industry, this taper pin can be used to connect the engine timing gear and crankshaft. The combination of the rust resistance of the black oxide film and the strength and toughness of the pin can resist high temperatures and vibrations during engine operation, preventing failures caused by gear misalignment.

Furthermore, in the fields of precision instruments and medical equipment, this taper pin also demonstrates unique value. For instance, in the fixing of lens holders in optical instruments, the dimensional accuracy brought by GB117 ensures that the positioning deviation between the holder and the machine body is less than 0.005mm, without affecting the imaging effect of the optical system. In the connection of components in dental treatment equipment, the rust resistance and low-friction characteristics of the black oxide finish can not only meet the cleanliness requirements of the medical environment but also ensure the stability of the equipment during frequent operations.

IV. Usage Precautions: Key to Maximizing Performance and Service Life

To give full play to the performance of the 40Cr alloy steel taper pin with flat ends and black oxide finish (GB117), the following points should be noted during use: Before assembly, check whether the pin surface has black oxide film peeling, scratches, or rust. If defects are found, replace the pin in a timely manner to avoid affecting the protective effect and fitting accuracy. During assembly, ensure that the tapered hole is processed in accordance with GB117 requirements (e.g., taper 1:50, surface roughness Ra≤1.6μm) and clean impurities in the hole to prevent uneven force on the pin caused by foreign objects. When installing, use a dedicated pressing tool to apply uniform axial force; avoid directly striking the flat ends of the pin with a hammer to prevent flat end deformation or black oxide film damage.

In terms of maintenance, regularly check the fastening status of the taper pin. Especially for equipment with frequent vibrations, it is recommended to conduct loosening inspections every 3 months. If the black oxide film on the pin surface is damaged and slight rust appears, temporary protection can be provided by applying anti-rust grease. However, if the rust depth exceeds 0.1mm, the pin should be replaced immediately to prevent rust spread from affecting the connection strength.

With the synergistic advantages of material, craftsmanship, and standards, the 40Cr alloy steel taper pin with flat ends and black oxide finish (GB117) has become a reliable choice in the field of precision fastening. Whether in high-strength industrial scenarios or high-precision instrument equipment, it can guarantee structural safety with stable performance, providing solid support for efficient production and reliable operation in various industries.